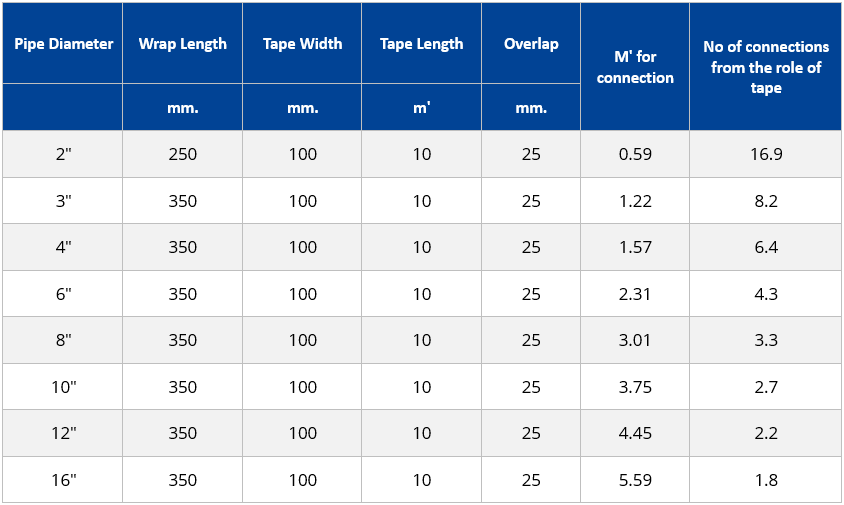

A shrink tape type SHT-330 is used to wrap welding heads and pipe accessories in the field. The role of the tape is to protect the welding from corrosion. The tape is comprised from a cross-linked polyethylene and an internal layer made from a Butyl rubber based compound.

Characteristics

- No primer is required prior to coating with a shrink tape.

- The tape has excellent durability against corrosion, impact and penetration.

- The tape has excellent durability against periodic changes in temperature, ground stress, hydrostatic pressure and chemical corrosion.

- The tape excels with great durability against Cathodic Disbonding, microorganisms and bacteria.

- Easy application in all pipe diameters and suitable for repairs and for coating all types of accessories in the field.

- No expert workers are required for application. The tape is applied within minutes by using a gas blowtorch.

Technical information

Uses

- Anti-corrosive protection of head connections of water and gas pipelines.

- Anti-corrosive protection of pipeline accessories such as arcs, tames, connectors etc.,

- Clean the weld with a mechanical steel brush.

- Heat the welded area or the area designated for coating to a temperature of 60⁰

- Attach the end of the tape to the wrapping starting point, heat with a gas blowtorch and fasten the tape to the surface using a glove.

- Wrap the tape around the pipe in the area designated for wrapping with an overlap of at least 15mm (do not use a primer).

- At the end of the wrapping cis to the pipe, start with one end and continue to the other end, heat evenly around the pipe, ensure the escape of trapped air, wait for complete cooling.